LSL INJECTORS

The LSL-32, LSL-1, LSL-R5, LSL-HO & LSL-11 injectors, put simply out-spec the competition by offering higher performance, more standard inclusions, more options and better service life than competitor brands.

LSL-32 injectors

Out-Spec the competition

They have 50% higher grease output than competitor brands within the same frame size

They are made in 303 SS vs zinc plated steel used on competitor brands

They are available in standard and high vent versions with the high vent versions reset pressure 3 times other standard versions and 50% higher than other competitor high vent injectors. (equal to SL-1 injectors)

They are available in banks from 1 injector to 10 injectors where other competitor brands only go up to 4 injectors

They have an optional cross porting bar for joining two injectors thus providing outputs of 3 times other competitor brands. These crossporting options are not offered by competitor brands

The LSL-32 injectors indicator pins are parallel to the lubrication outlet and not perpendicular thus providing additional impact resistance over competitive brands

The LSL-32 injectors have optional colour coded spectrum sleeves not offered by competitor brands

LSL-1A injectors

Out-Spec the competition

They are rated to 5000-psi whereas competitive brands are only rated to 3500-psi

The springs are made from chrome silicon valve wire with significantly higher service life than competitor brands

They have significantly greater flow paths than competitor brands meaning they reset much quicker and are not prone to waxing like other units

They come standard with dust caps unlike competitor brands where these are sold separately at up to 16% of the replacement injector cost

They have a honed valve assembly compared with the rubber packing design used by competitor brands.

LSL-R5 injectors

Out-Spec the competition

They are rated to 6000-psi which matches the highest pressure ratings of all competitor brands but at a fraction of the cost

The springs are made from chrome silicon valve wire with significantly higher service life thanc ompetitor brands

They don’t have negative pressure ratios like other competitor brands which means more output pressure for the same inlet pressures

They have a honed valve assembly compared with the rubber packing design used by competitor brands

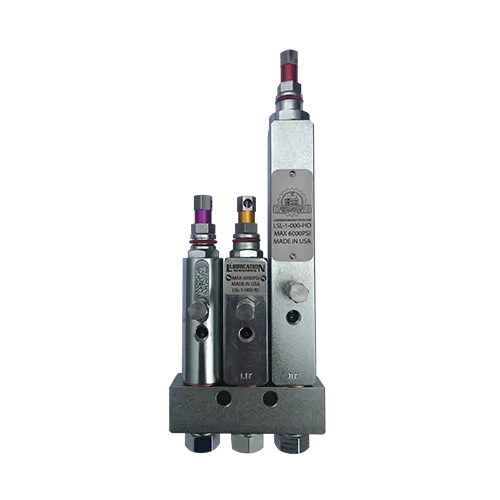

LSL-HO injectors

Out-Spec the competition

They are rated to 6000-psi which matched the highest pressure ratings of all competitor brands but at a fraction of the cost

The springs are made from chrome silicon valve wire with significantly higher service life than competitor brands

They don’t have negative pressure ratios like other competitor brands which means more output pressure for the same inlet pressures

They have a honed valve assembly compared with the rubber packing design used by competitor brands

LSL-1A-000-HO-LM5 Liebherr replacement injectors available to suit LM5 manifolds not offered by competitor brands

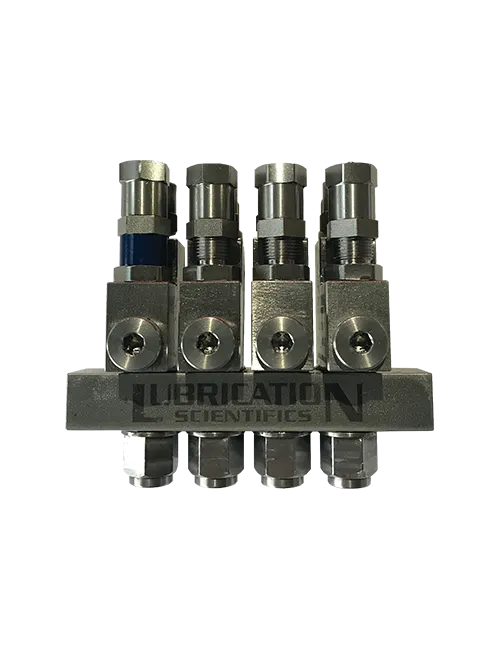

LSL-11 injectors

Out-Spec the competition

They are rated to 5000-psi whereas competitive brands are only rated to 3500-psi

The springs are made from chrome silicon valve wire with significantly higher service life than competitor brands

They come standard with dust caps unlike competitor brands where these are sold separately at up to 3% of the replacement injector cost

MOST RELIABLE, MOST FLEXIBLE & BEST VALUE

LSL injectors are available in a range of configurations to suit almost any application (Including retrofitting to existing systems) and in many systems can work without the need for changing any other system components. Simply select the outlet volumes you require and order the components or factory assembled banks accordingly.

Standard Features

All come standard with dust caps (unlike other brands)

All are compatible with competitor manifolds including the LM5 adaptor option adapting to Liebherr manifolds

All manufactured in USA from the highest quality steels

All have manual lube provisions

LSL-32, 1, R5, HO all available with adjustment spectrum sleeves

Four Different Displacement Options

LSL-32 Max 0.196-cc/cycle Min 0.016cc/cycle

LSL-HO Max 5.0-cc/cycle Min 0.50cc/cycle

LSL-1 & R5 Max 1.31-cc/cycle Min 0.131cc/cycle

LSL-11 Max 8.2-cc/cycle Min 0.82-cc/cycle

Three material selections for all injectors

Zinc plated Steel

303 stainless

316 stainless